With innovations resulting in exceptional component design and reliable operation, the replacement parts of gyratory crusher offered by CSP are designed to exceed customer expectation in production targets, minimizing operational costs and meeting the challenges of high capacity mining installation.

The supply scope of main gyratory crusher parts contains 6 models:

4265 gyratory crusher

5065 gyratory crusher

5475 gyratory crusher

6089 gyratory crusher

6275 gyratory crusher

60110 gyratory crusher

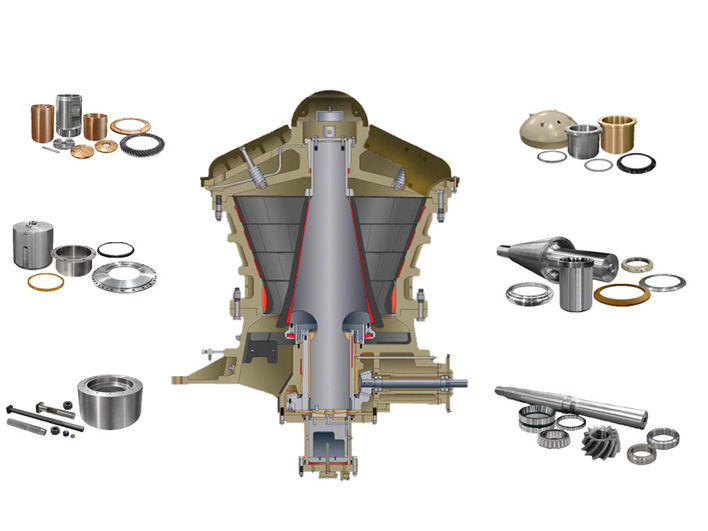

The gyratory crusher can be divided into six assemblies: Spider assembly, mainshaft assembly, pinionshaft assembly, Eccentric assembly, Hydroset assembly and additional component. Each assembly is made up of four to seven parts. CSP can offer the spider assembly, Mainshaft assembly, pinionshaft assembly, eccentric assembly, hydroset assembly and additional components.

Features of gyratory crusher parts

Designed for service requirements and ease of operation, the parts of primary gyratory crusher supplied by CSP will be ready to fit any existing or proposed gyratory crushing plant.

- Rigid one-piece steel spider distributes impact and crushing forces over the entire rim with no wear or separation found with two-piece designs

- One piece forged mainshaft eliminates the possibility of separation during operation

- Mainshaft Position System controls the vertical adjustment of the mainshaft to compensate for liner wear

- Counterbalanced design makes the crusher ideal for mobile or stationary installations and minimizes the forces transmitted into the supporting structure

- Mainshaft threads located on a separate steel sleeve reduces stress on the Mainshaft

- External gear and pinion backlash adjustment simplifies and speeds maintenance

- Patented step bearing wear indicator identifies worn bearings, eliminating guessing or having to disassemble the crusher to conduct an inspection

- Top serviceable spider bushing and oil seal shortens maintenance intervals

- Standard manganese concaves for cost effective performance with available alloy and double tiered concaves for longer life and fewer parts

- Nitrogen charged balance cylinders ensures that step components do not separate in the event of a Mainshaft jump

- Available automation system to monitor oil pressures and temperatures and bearing conditions to ensure a healthy crusher

- Optimal bushing design allows the crusher to operate as efficiently as possible, minimizing mechanical losses and heat dissipation